Metal parts & structures

ROMRADIATOARE has proven abilities to assimilate and successfully manage a broad portfolio of metal parts ranging from simple parts to complex assemblies.

Our ISO 9001:2015 certified metal fabrications process ensures consistent on-time, on-cost and on-quality deliveries to our partners.

Our standard materials include: steel, stainless steel, galvanized steel, aluminum, brass.

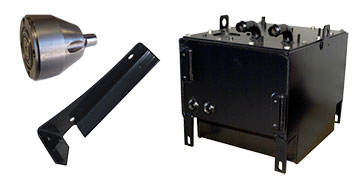

Our product portfolio includes: tractors and other agricultural machinery components, truck components, brackets and other car safety belt components, hydraulic & pneumatic tanks, windshield replacement parts, various machined parts, enclosures for home appliances and electrical equipment.

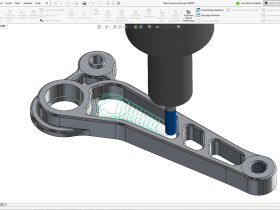

Our company’s modern technological facilities allows us to develop different sets of operations for manufacturing steel parts and structures: